Before MIG welding collision repair, a meticulous vehicle inspection and surface preparation are vital. Technicians assess structural integrity, removing visible and hidden damage with specialized tools. Panel removal grants access to concealed issues, ensuring comprehensive repair. Skilled professionals clean, sand, and prime surfaces to prevent post-weld problems. This thorough process, including proper panel replacement or car scratch repair, is key to successful MIG welding collision repairs.

Preparing a vehicle for MIG welding collision repairs involves meticulous steps to ensure structural integrity and seamless finishes. This guide walks you through the process, from assessing damage and preparing the surface to setting up the MIG welding system and performing precise techniques. Learn how to inspect for collision damage, remove parts, clean the work area, sand and prime metal surfaces, select and calibrate equipment, and achieve strong welds that rival the original craftsmanship. Master these steps, and you’ll be ready to tackle MIG welding collision repairs with confidence.

- Assessing the Damage and Preparing the Surface

- – Inspecting the vehicle for collision damage

- – Removing damaged parts and panels

Assessing the Damage and Preparing the Surface

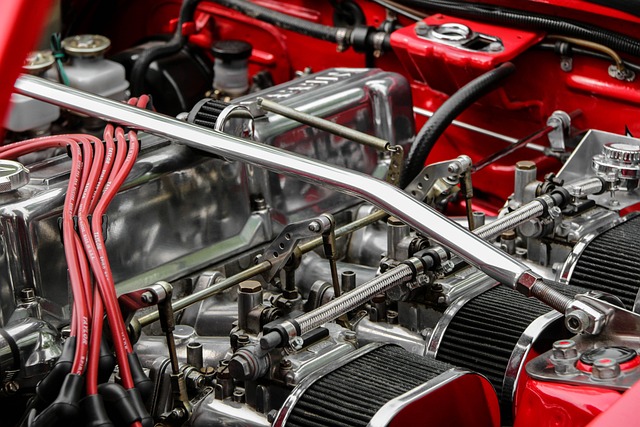

Before beginning any MIG welding collision repair, it’s crucial to thoroughly assess the damage and prepare the surface. Start by examining the vehicle for dents, dings, or other cosmetic imperfections that need to be addressed. In many cases, dent removal techniques like paintless dent repair can be employed to restore the car’s original appearance without extensive body work. Once all visible damage has been identified and addressed, shift focus to structural integrity. If frame straightening is required, ensure the metal is aligned accurately to avoid complications during the welding process.

The surface preparation stage is essential for achieving strong, lasting welds. This involves cleaning the area thoroughly to remove any grease, dirt, or debris that could impede fusion. Sanding and priming are often necessary steps to create a smooth base for the MIG welding process. Proper surface prep not only ensures better bonding but also reduces the risk of post-weld issues like rust or paint flaking.

– Inspecting the vehicle for collision damage

Before beginning any MIG welding collision repair, a thorough inspection of the vehicle is paramount. This step involves meticulously evaluating every inch of the car to identify all damage resulting from the collision. Skilled technicians will look for cracks, dents, and deformations both visible and hidden, as even minor imperfections can affect the structural integrity and overall quality of the repair.

During this process, consider utilizing specialized tools like torches or pressure sensors to uncover concealed damage, such as shattered metal or hidden panel warping. This meticulous inspection ensures that no aspect of the vehicle’s structure goes unaddressed, setting a solid foundation for successful MIG welding collision repairs in an auto body shop. Remember, only after a comprehensive assessment can the most effective strategies for car dent repair and auto body services be implemented.

– Removing damaged parts and panels

Before beginning any MIG welding collision repair process, it’s crucial to thoroughly inspect and prepare the damaged vehicle. The first step involves carefully removing all visibly damaged parts and panels. This meticulous process requires both precision and safety precautions, as incorrect handling can lead to further complications. Skilled technicians use specialized tools to gently disassemble components, ensuring they are properly secured for safe removal.

Proper panel removal is a critical aspect of vehicle repair services, especially in a collision repair center. It allows access to the underlying structure, enabling technicians to assess and address hidden damage. After carefully separating the damaged panels from the rest of the car body, these components can be set aside for either replacement or specialized car scratch repair, depending on the extent of the scratches and dents.

Preparing a vehicle for MIG welding collision repairs involves meticulous assessment and surface preparation. By thoroughly inspecting for damage, removing affected panels, and ensuring a clean, degreased surface, you create an ideal environment for precise and effective MIG welding. This process is crucial in achieving high-quality, structural integrity for collision repair, restoring vehicles to their pre-accident condition.