MIG welding collision repair has transformed the automotive industry by providing a versatile, efficient, and precise method for repairing both classic and modern vehicles. Using inert gases like argon or carbon dioxide, this advanced process offers faster welding speeds, improved strength, and superior structural integrity compared to traditional methods. MIG welding's adaptability and eco-friendly nature make it the preferred choice for skilled technicians aiming to restore vehicles to their pre-collision condition with high-quality outcomes, becoming a game-changer in auto body painting and collision repair services.

In the realm of automotive restoration, MIG welding collision repair has emerged as a game-changer, offering precise and robust solutions for both classic and modern vehicles. This article delves into the world of MIG welding, exploring its capabilities and advantages in collision repair. From understanding the technique to its successful application on diverse vehicle models, we uncover why MIG welding is a top choice for professionals. Discover the benefits, considerations, and the art behind repairing cars with this powerful method.

- Understanding MIG Welding: A Powerful Technique for Collision Repair

- The Art of Repair: Applying MIG Welding to Classic and Modern Vehicles

- Benefits and Considerations: Why Choose MIG Welding for Your Collision Repair Needs?

Understanding MIG Welding: A Powerful Technique for Collision Repair

MIG welding collision repair has emerged as a powerful technique for both classic and modern vehicles. This advanced process involves using a metal inert gas (usually argon or carbon dioxide) to shield the weld area from oxygen, enabling higher welding speeds and improved strength compared to traditional methods. The versatility of MIG welding makes it suitable for a wide range of materials, from thin sheet metal to thicker components, making it a go-to choice for efficient vehicle repair services.

In the realm of car damage repair, MIG welding offers precision and accuracy, allowing skilled technicians to restore vehicles to their pre-collision condition. Moreover, its ability to create strong, clean welds facilitates seamless integration during auto body painting, ensuring superior structural integrity and aesthetic appeal. As such, MIG welding collision repair has become a game-changer in the industry, providing both effective solutions for vehicle repair services and high-quality outcomes for car owners seeking top-notch auto body painting.

The Art of Repair: Applying MIG Welding to Classic and Modern Vehicles

The art of repairing vehicles through MIG welding is a precise and versatile skill that transcends generations of automobiles. Whether tackling classic cars with their intricate curves and vintage charm or modern designs with complex metalwork, MIG welding collision repair offers an unparalleled level of precision and strength. This method involves using a gas metal arc welding process to fuse metal together, creating strong bonds that match the original structure’s integrity.

For auto detailing enthusiasts and automotive collision repair specialists alike, MIG welding is a game-changer in auto body work. It allows for clean, seamless joints, ensuring the restored vehicle retains its aesthetic appeal while meeting structural requirements. The technique’s adaptability makes it suitable for various metal types and thicknesses found in both classic and modern vehicles, making it an indispensable tool in the industry.

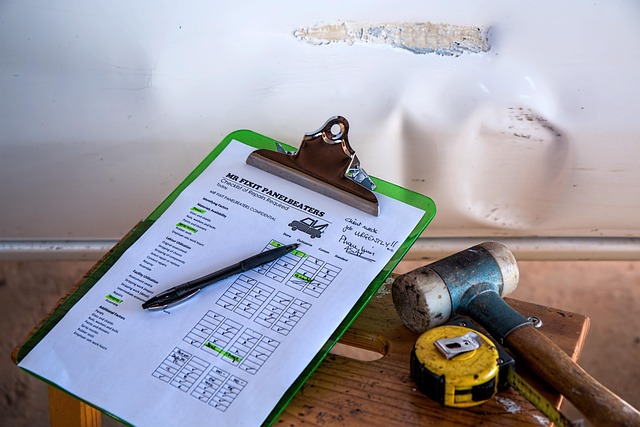

Benefits and Considerations: Why Choose MIG Welding for Your Collision Repair Needs?

MIG welding is a highly effective and popular choice for collision repair services, offering both precision and strength. When it comes to repairing classic or modern vehicles, this technique provides an array of advantages. Firstly, MIG welders can create strong, clean, and consistent joints, ensuring structural integrity and longevity in the repaired vehicle. This precision allows for minimal material waste, making it an environmentally friendly option, a significant benefit for eco-conscious auto body shops.

Moreover, MIG welding is versatile, suitable for various metal types commonly found in both classic and contemporary car models. Its non-destructive nature also means less risk of damage to the surrounding area during the repair process, preserving the vehicle’s original aesthetic. Unlike some other methods, it doesn’t require extensive surface preparation, saving time and resources at the collision repair center. This efficiency translates into quicker turnaround times without compromising quality, making MIG welding a top choice for auto painting and restoration work.

MIG welding collision repair offers a powerful and versatile solution for both classic and modern vehicle restoration. Its ability to create strong, precise bonds with minimal heat input makes it ideal for preserving historical integrity while ensuring structural integrity. By leveraging this advanced technique, collision repair shops can deliver high-quality results that meet the demanding needs of car enthusiasts and original equipment manufacturers alike. Choosing MIG welding for your collision repair project ensures a durable, efficient, and aesthetically pleasing finish.